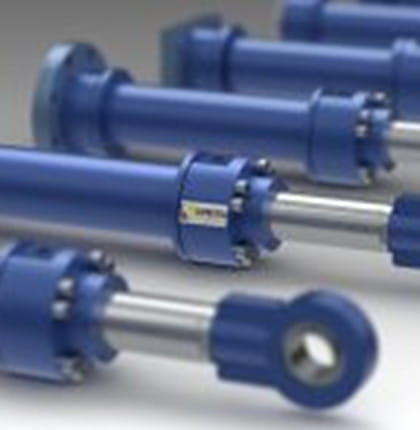

Single-Acting vs Double-Acting Hydraulic Cylinders: Key Differences and Uses

Hydraulic cylinders find several applications in numerous industrial, building, and production activities. They transform hydraulic energy into linear motion and force. Single-acting and double-acting hydraulic cylinders are the most widespread of the types that are in use. Although their fundamental use is still the same, which is to generate controlled linear movement, functionality, efficiency, and optimal applications differ greatly. This knowledge of these differences will assist in choosing the appropriate cylinder that would give the best performance, safety, and cost-effectiveness.

HOW THEY WORK

A hydraulic cylinder is a single acting cylinder that utilises hydraulic pressure in a single direction. The fluid causes the piston to travel in a single direction, which in most cases is stretching it. The retraction is either through gravity, mechanical springs or external load. Due to the pressure being exerted on a single side of the piston only, this design leads to the production of a simplistic design and less components.

Conversely, a hydraulic cylinder that is a double-acting hydraulic cylinder employs hydraulic pressure in both directions. The extension and retraction of the piston is controlled by introductions of fluid in both directions around the piston using separate ports. These two-pressure cylinders render the double acting cylinders more powerful, versatile and precise.

KEY DIFFERENCES

1. Direction of Force

- Single-acting: The force is exerted in a single direction. Retraction is passive. Double-acting: Push is done on extension and on retraction, which gives more control and performance.

2. Complexity and Construction

- Single acting: Less complicated design, less seals and ports, less chances of leakage and less difficult maintenance.

Two-port, two-component sealing: More complicated and requires more sealing parts, but has better performance.

3. Control and Precision

Single-acting This type can only be used in cases in which the control of retraction is not important.

- Double-acting: The option would allow a specific, defined movement that is possible in any of the two directions which is why it would be appropriate to the rigorous operations.

4. Power and Efficiency

- Single-acting: Suitable in those requirements where forces are needed in only one direction; energy-saving in mechanical ease.

- Double-acting: Increased power and reduced cycle times by active force in both directions.

5. Cost

- Single-acting: This is typically cheaper upfront but expensive to maintain.

- Double-acting: More initial cost since it is more complex but it has higher performance value.

COMMON USES

Single-Acting Cylinders are ideal when the workload naturally assists retraction. Typical applications include:

- Hydraulic jacks: Where gravity returns the piston.

- Trash compactors: Pressure is needed only for compression.

- Lifting equipment: When loads lower under their own weight.

- Agricultural machinery: For simple, one-directional movement tasks.

These cylinders shine in scenarios requiring simplicity, durability, and cost-effectiveness, particularly where space is limited and only one directional force is needed.

Double-Acting Cylinders, with their precision and bilateral force application, are used in:

- Construction machinery: Excavators, loaders, and cranes for active control in all movements.

- Industrial automation: Manufacturing presses, robotics, and injection moulding machines.

- Marine equipment: Steering and deck machinery requiring stable two-way control.

- Agricultural attachments: Such as plows and harvesters where bidirectional control is essential.

They are preferred where accurate motion, heavier loads, and high cycle speeds are necessary.

A FINAL WORD

Single or double act hydraulic cylinders are defined by application requirements. Single acting cylinders are easy, dependable and inexpensive in the case of a single-way force. The double-acting cylinders work better and are more accurate in processes where constant and controlled force in both directions are needed particularly when large loads or varied loads are involved.

Know their distinct features and their best applications to achieve maximum efficiency of hydraulic systems, component lifetime, and performance.

Other Link: Exploring different Types of Hoists and their Applications